Unique Technical Advantages

The Arterran Thermo-Catalytic Conversion (TCC) process was developed by the founder of the company over a ten-year period of intensive R&D.

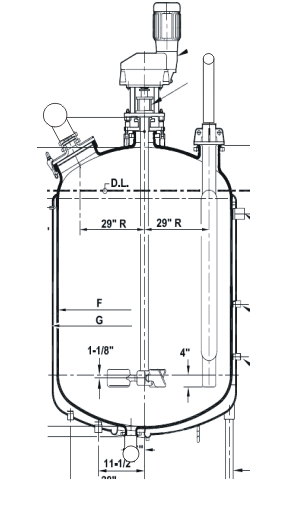

The TCC technology converts lignocellulosic biomass and uses lower temperature and lower pressure in an industry-standard reactor vessel to homogenize the biomass after which the slurry is mechanically separated. The solid portion is then densified into a pellet fuel. The resulting Arterran Fuel is then converted to a water-resistant and transportable fuel with an energy density range suited to replace bituminous or anthracite coal.

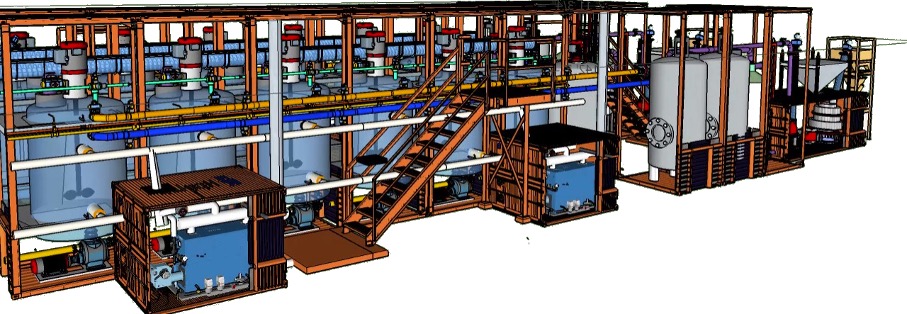

The key to the manufacture of a water-repellent pellet is a process that forces the biomass to shed as much water as is economically possible. Arterran’s proprietary cleantech production process provides an efficient and inexpensive modular manufacturing system for the conversion of residual biomass into an energy-dense, hydrophobic solid biofuel specifically designed to renewably replace thermal coal.

Arterran’s next-generation renewable fuel empowers thermal generators with the ability to expedite thermal coal’s displacement, from 1 to 100%, without the need to incur cost prohibitive power.